Pier Pressure

State

to enforce weight limits

on Milton-Madison Bridge

Tests

of 80-year-old piers

may determine decision on whether

to build new or use existing pillars

"If we didn’t feel the bridge was safe,

we would close it down." – Andrea Clifford,

Public Information Officer for Ky. Transportation Cabinet

By

Konnie McCollum

Staff Writer

|

|

April 2009 Indiana & Kentucky Edition Cover |

(April 2009) – A longstanding, vital Ohio River

crossing for interstate commerce between Indiana and Kentucky is about

to be shut down for an indeterminable time. That’s because the

Milton-Madison Bridge is deteriorating at a faster rate than officials

anticipated, according to a December 2008 biennial inspection.

As a result, a 15-ton weight limit that will ban loaded semis and other

heavy vehicles from the 80-year-old bridge will go into effect in early

April. Kentucky Transportation Cabinet officials call the weight limit

a precautionary measure until repairs can be made to the damaged parts.

They plan to post signs to warn truckers of the new weight limit and

task highway enforcement officers to monitor the restrictions.

Vehicles weighing more than 15 tons must take an alternate route to

cross the Ohio River. The nearest Ohio River bridges are 46 miles downstream

in Louisville, Ky., and 26 miles upstream at Markland Dam above Vevay,

Ind.

Although the permanency of the weight restriction won’t be known

until repairs and an in-depth inspection have been made, the issue has

again raised questions about the urgency of replacing the functionally

obsolete and structurally deficient bridge.

“If we didn’t feel the bridge was safe, we would close it

down,” said Andrea Clifford, Public Information Officer for District

Five of the Kentucky Transportation Cabinet. “We saw more rapid

deterioration than seen in the last fracture critical report done in

2006. We implemented the weight restriction because we want to prevent

the problems from deteriorating further.”

|

| • For more information about the Milton-Madison Bridge Project, visit: www.MiltonMadisonBridge.com. |

At issue is deterioration on a gusset plate on the Indiana

side of the main truss, several vertical posts in the deck trusses and

two splice plates on the lower chord of the small truss, said Clifford.

After the repairs are finished by the end of the summer, the bridge

will be inspected “like a fine tooth comb,” said David Steele

of the Kentucky Transportation Cabinet. “We’ll decide after

that whether to lift the (weight limit) restriction.”

Corey Murphy, executive director of Madison’s Economic Development

Partners, said as long as the weight limit is temporary, there will

be ways for businesses to work around the issue. “If it becomes

permanent, that will be another challenge. Looking at the positive side

of this, we are going to use this opportunity to keep pushing forward

in clear, concise agreement for a new bridge. Time is of the essence.”

Carrying

the load on the bridge

Several area trucking companies also hope the weight restrictions

are not permanent. At Madison Tool and Die, owner Gary Sparks said the

new weight limit is “pushing us on extra mileage and time.”

He wasn’t sure if his company would be able to pass those costs

onto his customers. “More than 30 percent of our business will

be affected,” he said.

In Milton, Indiana-Kentucky Trucking Inc. runs more than 60 trucks a

day across the bridge. Owner Robert Parker said the effects of the limit

depend on how long it is in place. He said the 1997 rehabilitation was

tough on his company, a building materials trucking firm that has been

in business since 1978.

“We couldn’t come across the bridge loaded or unloaded because

of width restrictions,” he said. “This time at least it sounds

like we will be able to cross unloaded.” His semi-trucks weigh

24,000 pounds when empty.

|

He worried about competition setting in because of the

extra charges that will be tacked on for the extra mileage his drivers

will be forced to go. “This is going to affect all of us, from

the cost of steeper groceries to people building homes,” he said.

Clifford said the $200,000 needed for the bridge repairs will come from

a bridge maintenance fund, and Indiana and Kentucky will equally share

the cost. She said this setback doesn’t impact the Milton-Madison

Bridge Project, a three-year, $5 million engineering study for a bridge

replacement led by Wilbur Smith Associates of Lexington, Ky. “Both

transportation departments are committed to solving the problems in

an expeditious manner.”

Already, the project has worked to develop a purpose and needs statement,

part of the necessary federal requirements that will help screen and

narrow the options for the project.

There are currently four options for the project that all have to be

considered:

• Do Nothing Option: This would eventually result in the

total closure of the bridge for vehicle traffic by 2025.

• Rehabilitation Option: This would slow the rate of deterioration

but could result in full closures totaling 12-18 months.

• Superstructure Re-placement: This would use existing piers

and widen them for a wider superstructure. It would be more cost-effective

and possibly faster than a new bridge on a new location, but would result

in a nine-month closure, officials said. The superstructure replacement

would depend on whether tests on the existing piers determined this

option is a possibility. The superstructure consists of that portion

of the bridge above the bearings, including the deck, handrail, curbs,

floor system and structural members.

• New bridge on a new location: Several new locations

have been identified, and a screening process will narrow those options.

“We are trying to move as quickly as possible. We

have a sick bridge, although I’ve seen much worse,” said John

Carr, a Wilbur Smith Associate who serves as the project manager.

“We bought some time with the 1997 rehabilitation, but if we have

to do another one, we may not be able to keep the bridge open at all

during it.” Another rehabilitation project would slow everything

down and could actually keep the bridge closed longer than a superstructure

replacement, he said.

There would be advantages and disadvantages for a superstructure replacement.

The cost would be far less than that of a new bridge, and there would

be considerable time savings.

“If we choose to put a new superstructure on top of the existing

piers, we could possible have that done within three years, but it would

mean a bridge closure for up to nine months,” said Carr. “In

today’s environment, we need to carefully work to make money stretch.”

Testing

the piers

|

|

Carr |

Already, geotechnical crews from the Kentucky Trans-portation

Cabinet have worked to obtain pier core samples from the bridge. Engineers

will test the viability of the existing piers, which could be used during

a replacement of the superstructure, an alternative being considered

for the Milton-Madison Bridge Project. Results are expected in the spring

of this year.

Bart Asher, a civil engineer in the Kentucky Transportation Cabinet’s

Division of Structural Design-Geotechnical Branch, said that the re-use

of foundations from one bridge to the next has been a fairly common

practice.

“Although many people believe that state government transportation

departments have deep pockets, we are also struggling to do more with

less funding, just like everyone else,” he said. “Revitalization

or reuse of all or part of an existing structure is an important tool.”

|

|

Asher |

He said one thing people need to keep in mind is that

historically, a good mixture of concrete actually gains strength over

time. “The normal compressive strength used in normal current designs

is 3,500 pounds per square inch. Preliminary results indicate that the

concrete samples taken from the Milton-Madison Bridge range from 6,000

to 13,000 pounds per square inch, which is very encouraging for the

reuse of the piers.”

“The level of testing for evaluation of the re-use of a substructure

will vary depending on the structure,” he said. “Sometimes

visual inspections and review of existing plans is all that is needed.”

In the case of the Madison-Milton Bridge, visual inspections are just

a part of the inspection. A major river bridge is defined as being more

than 500 feet in length, according to Carr. The current Milton-Madison

bridge has a span more than 600 feet.

|

|

Photo

by Don Ward Sean

Pickerrell of Elizabethtown, Ky., |

Asher said that in the visual evaluation, numerous inspections

of the visible portions of the piers have been undertaken by experienced

engineers and technicians. These inspections can tell officials a great

deal about a structure. “Some of the recent issues with the truss

that resulted in the weight limits were discovered in part from visual

inspections,” he said.

As part of those visual inspections, there were several methods used,

including impulse response, impulse radar, corrosion rate testing and

hammer soundings, which are basically tapping the concrete with a hammer

to evaluate its competence.

Also on the Milton-Madison Bridge, there was several other tests including

drilling. Asher said the drilling of the pier concrete from the top

of the pier and 50 feet into the bedrock was an important test because

it allowed engineers to examine the competency of the concrete from

the top of the pier all the way down.

“As you know, this bridge is 80 years old,” he said. “Construction

procedures were different in that era” There were questions that

needed to be answered as to how the concrete was placed, its homogeneity,

or makeup, and in general the quality control that was used in its placement.

“The drilling answered many of the questions,” he said.

Getting

to the bottom

The piers rest on bedrock. Retrieval of the bedrock cores

will allow the engineers to test the suitability of the bedrock under

the piers for the capability of supporting additional loads.

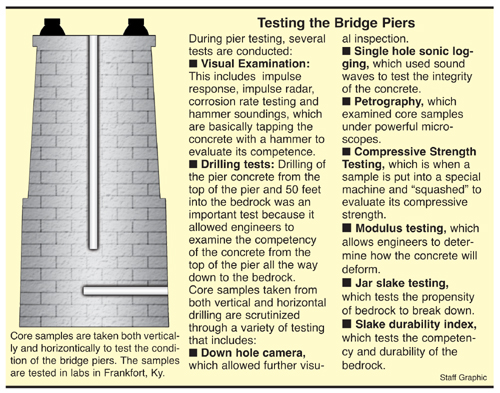

Many other tests are conducted on the samples (see graphic, page 22).

Asher said those tests are conducted so engineers and officials can

make an “informed decision” about whether the piers can be

reused. One of the firms involved in the project, Construction Technology

Laboratories of Skokie, Ill., will take the results and calculate the

anticipated remaining service life of the piers, he said.

During the testing of the piers, Asher said numerous problems were encountered

but none that were not resolved. One included extremely cold weather

during drilling, which caused extensive problems with sample retrieval.

|

|

Photo

provided Bart

Asher hangs from under the |

Another was the potential impact of extended drilling

on the Peregrine falcons who live on the bridge. The Kentucky Department

of Fish and Wildlife Resources helped resolve that issue.

Asher said the concrete was extremely hard and difficult to drill, and

several drill bits had to be tried in order to get through the piers.

“This is a good thing, though,” he said. They also hit numerous

pieces of steel in the pier that slowed drilling production.

During a superstructure replacement for a bridge, the piers would be

widened and new caps would be added. Carr said the bridge would be open

for traffic while that work is being completed.

Then the old steel of the bridge would be lifted off and dismantled,

and the new trusses and steel would be put back on using a crane.

|

|

Photo

provided The

core samples of |

A superstructure replacement would affect the design,

said Carr. Only arches and trusses could be considered. During a February

public meeting in which audience members were polled about their design

preferences, cable stay bridges were among the most popular.

“We could even build a truss that would be wider but that would

replicate the existing bridge,” said Carr.

Aaron Stover, a civil engineer at Michael Baker Corp., another firm

working in collaboration on the bridge project, said the idea of replacing

the superstructure of a bridge on existing piers is not new to Ohio

River Bridges.

Two projects, the Sewickley Bridge, just outside of Pittsburgh, and

the Williamstown Bridge over the Ohio River between Williamstown W.Va.,

and Marietta, Ohio, have already been completed.

“Our company is currently involved with several projects in Connecticut

and Pennsylvania, where the superstructure is being replaced,”

he said. “We have also completed similar project in Pennsylvania

and Ohio within the last five years.”

Stover noted that the Sewickley Bridge and the Williamstown Bridge piers

were 70 and 90 years old, respectively, when their superstructures were

replaced. Both bridges are still in service today.

|

|

Photo

provided A

drill bit used to cut |

Asher said his agency recently did an intensive investigation

on a stone masonry abutment, or bridge end foundation, which was built

in the pre-Civil War era. The re-use of that structure is still in question.

“We have re-used numerous foundations of stacked stone,” he

said.

In Wolfe County, Ky., a bridge is being constructed on a tall concrete

pier that is about 50 years old.

Only one of two piers on that bridge was re-usable.

The Roebling Bridge across the Ohio River between Cincinnati and Covington,

Ky., was constructed in 1866 and is still in use today. The pier towers

are original on that suspension bridge.

Carr said officials on the project are “well aware of the financial

burdens and hardships the communities.